Start of a new Burner Design

Posted: November 3, 2014 Filed under: Burner, Homemade Boiler | Tags: Arduino boiler control, boiler, Burn test, burner, homemade chip boiler 1 Comment A friend with Solidworks has offered to draw up a new burner, so I thought I would post a few pictures of the old burner to help with dimensions. Here’s a picture of the uncleaned burner with about two inches of ash build up in the bottom of the burner.

A friend with Solidworks has offered to draw up a new burner, so I thought I would post a few pictures of the old burner to help with dimensions. Here’s a picture of the uncleaned burner with about two inches of ash build up in the bottom of the burner.

The tape measure in this view gives a little help with size. Originally the back flap was designed to help with air flow a sort of chimney effect, however this was of limited help and probably helped trap ash as do the high sides.

The larger holes are 1/2″ and the ash still doesn’t fall through unless stirred.

PID continues to works great, efficiency measured

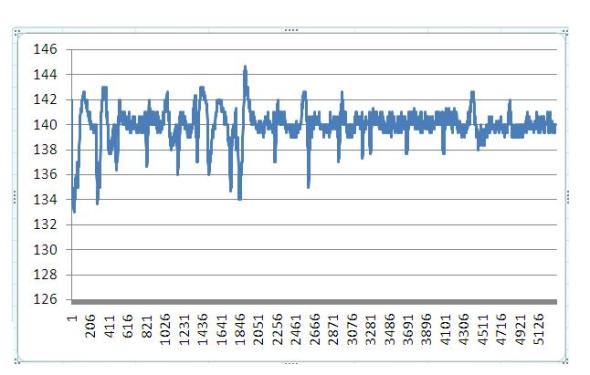

Posted: December 24, 2012 Filed under: Testing | Tags: Arduino, Burn test, homemade chip boiler Leave a commentThe PID control continues to work great, after 3 1/2 days the PID seems to be in good control. The graph shows a bit of variation but within 10 degrees which seems within bounds.

During this time period I used an average of 2.15 bags of pellets per day. At 40 lbs. per bag this is 86 lbs per day or 39.09 kg/day. At a cost of $216/ton. this is $9.28/day. I am hoping to reduce this to less than a dollar with chips but before I do, I intend to implement some more mechanisms to reduce fuel usage. More to come with the new year, Merry Christmas, Happy Holidays everyone.

3rd Burn Test

Posted: December 13, 2011 Filed under: Arduino, Homemade Boiler, LCD display | Tags: Arduino, Burn test, homemade chip boiler, hysteresis, relay chatter Leave a commentSuccess! At least compared to the last burn. Virtually no smoke, although some paint burned off. There is still some lingering smell from duct tape and caulking but overall much better, with no smoke. The burn start/ ash clean out door needs to be rebuilt with hinges, so that is still a problem area, but overall great. The program ran reasonably well, however, I added some hysteresis to the circulator loop to keep the relay chattering to a minimum. At this point I have the oil fired burner locked out, but I think I will reduce the temperature set point of the boiler and it just won’t come on unless needed. There are a list of small items that are required to run a 24 hour test, but I can probably do most of these things tomorrow and be able to be successful with this tomorrow afternoon. One thing that still needs to be done is shop cleanup. But for now, YEAH! Thanks

to friends!