Summer’s almost over, time to start thinking about heat

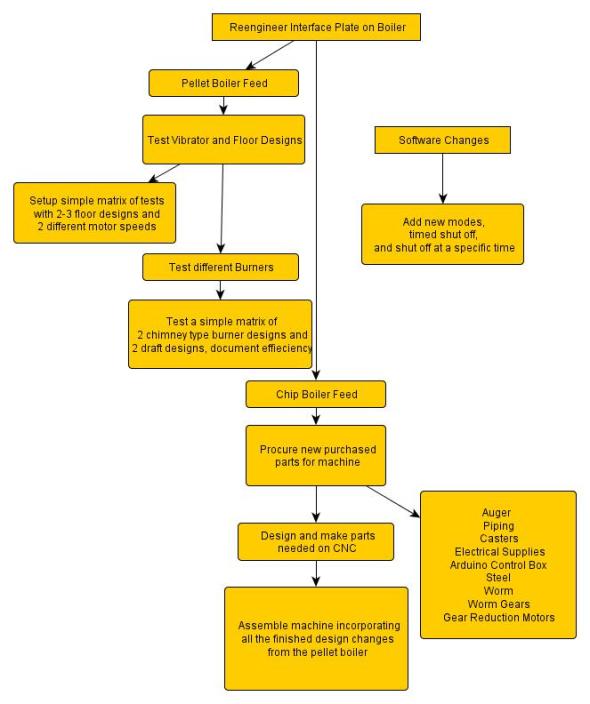

Posted: August 21, 2013 Filed under: Arduino, Data logging, Homemade Boiler, Hopper and Feed, Plumbing the boiler, Testing | Tags: Arduino, CNC Plasma, homemade chip boiler, welding project Leave a commentI know it’s early on the calendar but my focus is starting to shift back to my heating hobby. After two years of experimenting I have a proven performer with both the mechanical unit and the software I used last winter. I could change nothing and go through the winter fairly smoothly but there is always room for more improvement. So this is my plan: 1) Build a new unit very similar to the proven unit I have been using but with greater feed range capability to allow the unit to feed wood chips as well as pellets. By building a complete new unit I can always roll up the proven unit after the experiment is over and the data collected and resume heating without a hiccup. 2) Make slight modifications to the boiler to allow a larger interface plate between the feed unit and the boiler. This will allow a greater range of experimentation with burner designs. 3) Continue making small experimental changes to the working pellet unit such as a vibrator for ash removal, different burner designs, different draft designs. 4) Continue to make changes and improvements to the software. To start I would like three modes of operation. Continuous, run for some amount of time, and run until a set time. I changed the software to run to a set time by calendar date last spring but it was built into the software by date not menu or button choice. I would like to have the option of running for a few hours for both experimentation and also to occasionally heat hot water and be able to choose these options by menu. This fall I am sure I would like the unit to be able to take the chill off and then shut down. 5) Build a chip dryer. This is going to get to be a priority , I know the days are getting a little shorter and it is amazing how much less solar there is in the fall. Time to giddy up on that one.

I know I have to prioritize the work, and work as time and cash flow allows. But I think the first step will be to make a new interface plate and boiler opening. This will allow standardization for the next design and this work can be done while there is no particular need for heat. I went dumpster diving the other day and got a great new electrical box, so I guess I can get going on the that part of the new burner feed. I like free stuff. I may hit that dumpster again soon.

In the mean time it is still summer and there is still sailing weather.

Sizing the circulator pump

Posted: October 25, 2011 Filed under: Plumbing the boiler | Tags: Arduino, chip, circulator pump, pellet, welding 1 CommentToday my plan is to size the circulator pump from the chip boiler through the manifolds of the existing oil-fired boiler. The formula is: Q = h/(Cp*p*Delta T) Where Q is the heat transfer in Gallons per minute, Cp is the specific heat capacity, a constant based on the fluid, in this case water, p (really rho, I need help figuring out how to add greek letters and subscripts) and an assumed temperature drop or Delta T. Since it is my intention to run the chip boiler at 180°F and set the min temp on the oil burner at 130°F this will give me a 50°F temperature before the temp of the furnace requires it to fire. By leaving myself enough room I am hoping the Arduino controller and good temperature monitoring will preclude the oil boiler from firing. For the formula however I am going to assume a temperature difference of 20°F. So, again assuming a 30,ooo Btu chip boiler, a Cp for water of 1 BTU/Lbm/1°F, p (rho) the density of water, 62.34 lb/cu ft., Delta T=20°F and to convert BTU to gal/min 7.48 Gal/cu ft Therefore Q=30,000(7.48 gal/cu ft)/((1 Btu/lbm/1°F)(62.34 lb H2O/cu ft)(60 min/hr)(20°F)=2.9997 GPM

http://www.engineeringtoolbox.com/water-flow-rates-heating-systems-d_659.html

This formula gives the flow rate and now I need to calculate the pressure drop or head loss. The formula for this is:

Click to access SelectingCirculators.pdf

HL = k x c x L x (f1.75) Measuring the distance to the proposed location of the chip boiler, I get about 18′ of piping to and from the existing boiler and approx 10 of additional piping in the boiler, assuming 4 elbows. Planning on using either 3/4″ pex tubing or 1/2″ copper. Using Table 1 in the above link either 3/4″ pex or 1/2″ copper will be acceptable for a flow rate of 3 gpm. I would prefer to use the 1/2′ copper since it is a relatively short run and will require less hangers and difficulty doing a nice neat job through the utility room. From Table 2 I see a equivalvent feet of 1.55 for each elbow so 4 x 1.55 ft= 6.2 ft From Table 3, k =.0159, From Table 4 Water at 180°F, c=0.933, finally the flow rate raised to the 1.75 power is 6.83. So the total length is 18+6.2+13=37.2 ft. I calculate a rough head loss of approx. H loss=.0159*37.2*.933*6.83=3.77 ft Use the graph to find the correct pump having the conditions of 3 gpm flow and 3.77 ft of head It looks like a Taco 003 or a Taco 006 pump will work just fine. After some internet research using my normal internet heating component supplier I will probably use a Grundfos UPS 15-58FC, 3 Speed Circulator pump, 1/25 HP, 115 V

The lower manifold shown in the right hand picture is the cold return from the zones. I am planning on adding the hot water from the chip boiler in at this point to prevent the oil-fired burner from starting. This will also increase the heat reservoir by heating the water in the furnace as well. Lastly I plan on adding a 4th zone onto the existing manifolds to take advantage of the existing 2nd heating coil in a solar hot water tank I have separately heated by solar evacuated tubes. This will give additional options for the Arduino to dump heat.