Summer’s almost over, time to start thinking about heat

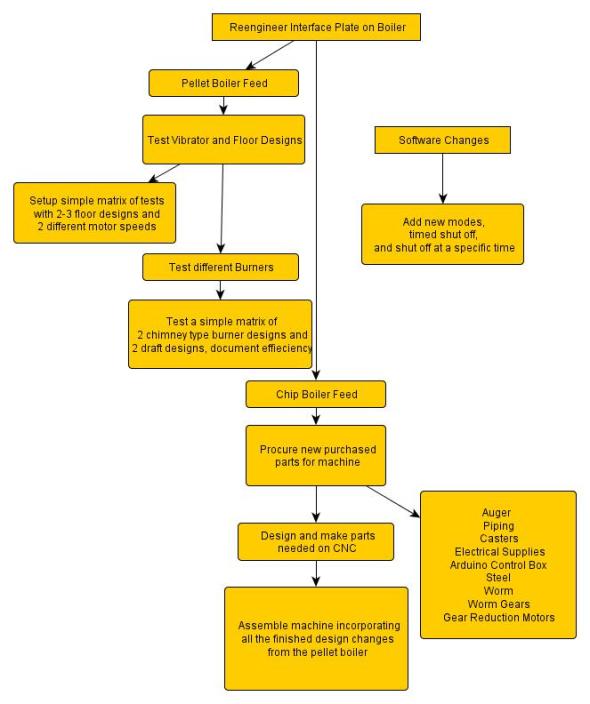

Posted: August 21, 2013 Filed under: Arduino, Data logging, Homemade Boiler, Hopper and Feed, Plumbing the boiler, Testing | Tags: Arduino, CNC Plasma, homemade chip boiler, welding project Leave a commentI know it’s early on the calendar but my focus is starting to shift back to my heating hobby. After two years of experimenting I have a proven performer with both the mechanical unit and the software I used last winter. I could change nothing and go through the winter fairly smoothly but there is always room for more improvement. So this is my plan: 1) Build a new unit very similar to the proven unit I have been using but with greater feed range capability to allow the unit to feed wood chips as well as pellets. By building a complete new unit I can always roll up the proven unit after the experiment is over and the data collected and resume heating without a hiccup. 2) Make slight modifications to the boiler to allow a larger interface plate between the feed unit and the boiler. This will allow a greater range of experimentation with burner designs. 3) Continue making small experimental changes to the working pellet unit such as a vibrator for ash removal, different burner designs, different draft designs. 4) Continue to make changes and improvements to the software. To start I would like three modes of operation. Continuous, run for some amount of time, and run until a set time. I changed the software to run to a set time by calendar date last spring but it was built into the software by date not menu or button choice. I would like to have the option of running for a few hours for both experimentation and also to occasionally heat hot water and be able to choose these options by menu. This fall I am sure I would like the unit to be able to take the chill off and then shut down. 5) Build a chip dryer. This is going to get to be a priority , I know the days are getting a little shorter and it is amazing how much less solar there is in the fall. Time to giddy up on that one.

I know I have to prioritize the work, and work as time and cash flow allows. But I think the first step will be to make a new interface plate and boiler opening. This will allow standardization for the next design and this work can be done while there is no particular need for heat. I went dumpster diving the other day and got a great new electrical box, so I guess I can get going on the that part of the new burner feed. I like free stuff. I may hit that dumpster again soon.

In the mean time it is still summer and there is still sailing weather.